Best management guide

Faba bean production: northern region

Australian industry

The Australian faba bean industry began in the 1980s and has grown steadily to become the world’s #1 exporter. Faba bean are now grown in all Australian grain production regions.

The large-seeded broad bean is well adapted to higher rainfall areas because of its higher yield potential, better disease and waterlogging tolerance and higher prices.

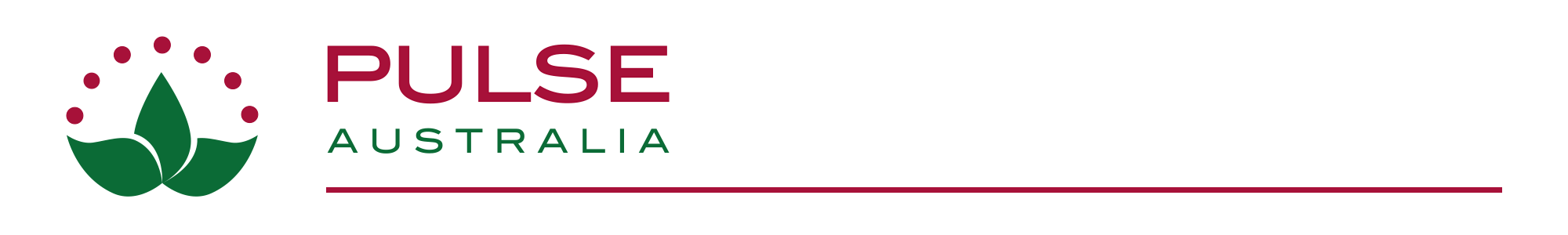

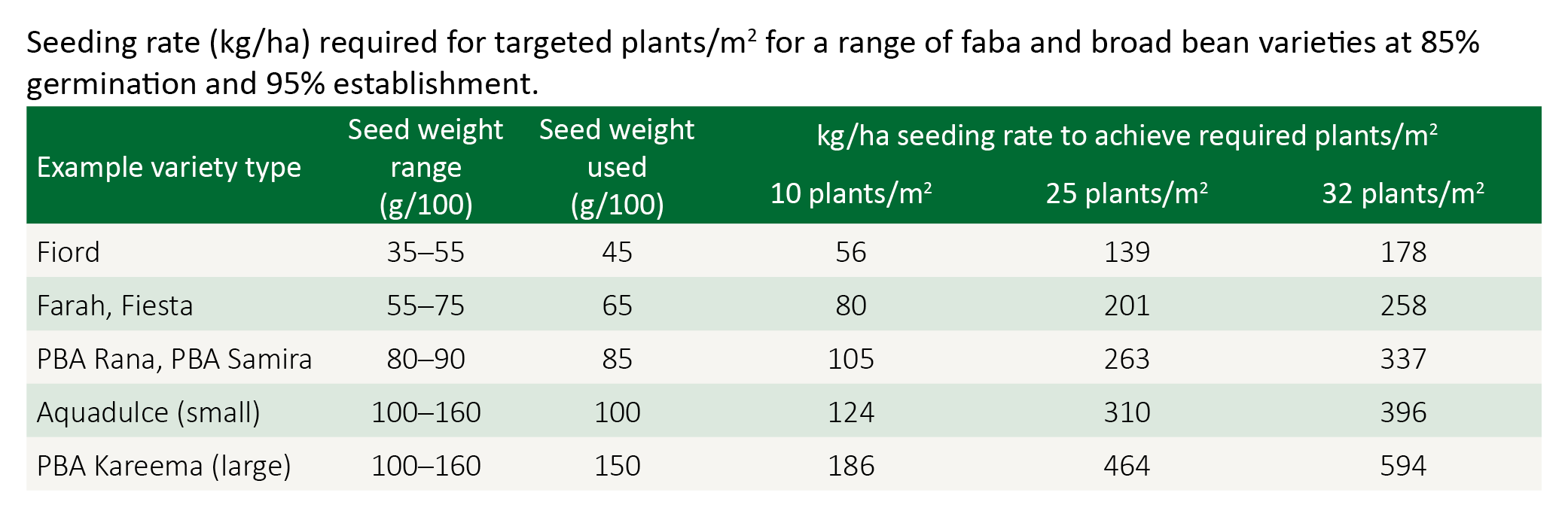

Bean types differ in shape and colour with sizes ranging the small seeded ‘Fiord type’ faba bean to medium size ‘Fiesta types’ to the larger PBA Rana. There is also the large seeded broad bean (Aquadulce and PBA Kareema) and the round horse or tic bean with small to medium sized seed.

Types

Faba bean

Faba bean (Vicia faba minor) originated in the Middle East and are now an important food crop in China and many Mediterranean and African countries. As faba beans receive greater attention in the western word, because of the value in livestock nutrition and crop rotation, there will be an increasing export potential for Australian grain.

Broad bean

Broad bean (Vicia faba major) is the same species as faba bean and markets are also similar (i.e. mainly Middle East) but they have a wider Australian use, for example they are exported to Southern Europe and also South East Asia where they are roasted for use as snack food.

The broad bean plant is virtually identical to the faba bean but has a slightly longer growing season and is therefore suited to regions of slightly higher rainfall (>500 mm) to achieve the seed size. Prime growing areas are the south-west of Victoria and south-east of South Australia. Like faba bean, broad bean tolerates waterlogging and the plants turn black at maturity.

Place in the rotation

Faba bean is a versatile and lucrative pulse crop in Australia that offers a number of rotational and financial benefits in many cropping systems.

| Advantages

|

Disadvantages

|

|

|

Faba bean, and especially broad bean, are not well suited to lower rainfall areas. If moisture is limiting, the plants do not grow to full height and the pods set close to the ground. They do not tolerate hot conditions during flowering, which can result in poor pod set and premature termination of flowering. Hot and dry conditions during flowering usually results in severe reduction in yield potential. Stubble retention and planting in wider rows can enable faba bean to be grown in lower rainfall areas and seasons.

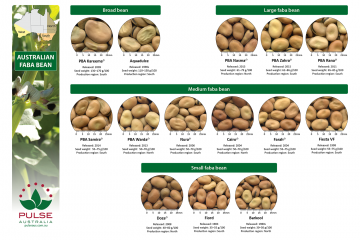

Faba bean and broad bean prefer well-drained loam to clay soils with a pH in the range of 6–9. They will not grow as well in light or acidic soils. They are known for being the pulse that is most tolerant of waterlogging, however to survive prolonged waterlogged conditions the plants must be well nodulated and foliar diseases must be controlled. Waterlogging will still impact on crop growth so although the plants will grow and set seed the plants are likely to be stunted and will yield less than plants growing in well-drained soil.

Faba and broad bean are moderately susceptible to hostile sub-soils, however boron toxicity, sodicity and salinity can cause patchiness in affected paddocks. Faba bean and broad bean do not tolerate exchangeable aluminium in soil. In the northern cropping zone, salinity and sodicity are the main constraints.

Keys to successful production

- Make faba beans part of an integrated cropping system involving wheat, canola or barley, or summer crops such as cotton, sorghum or maize. Take a systems perspective and assess financial performance over several seasons to determine the true benefits of faba beans in a rotation.

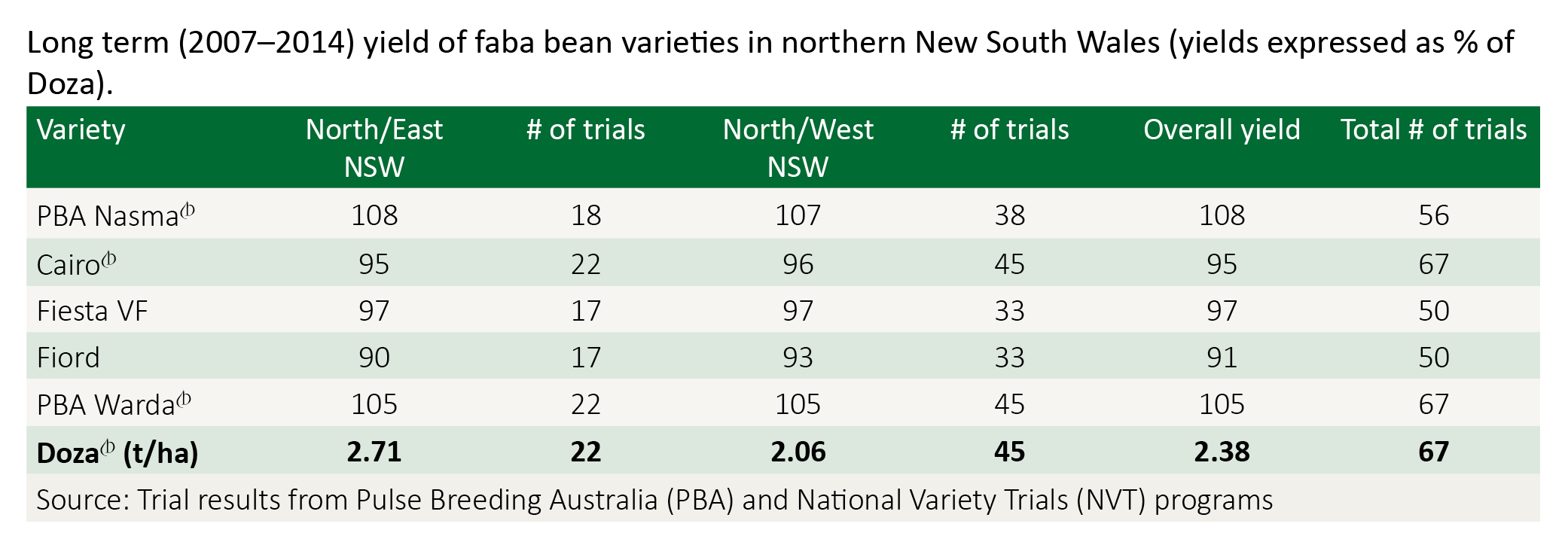

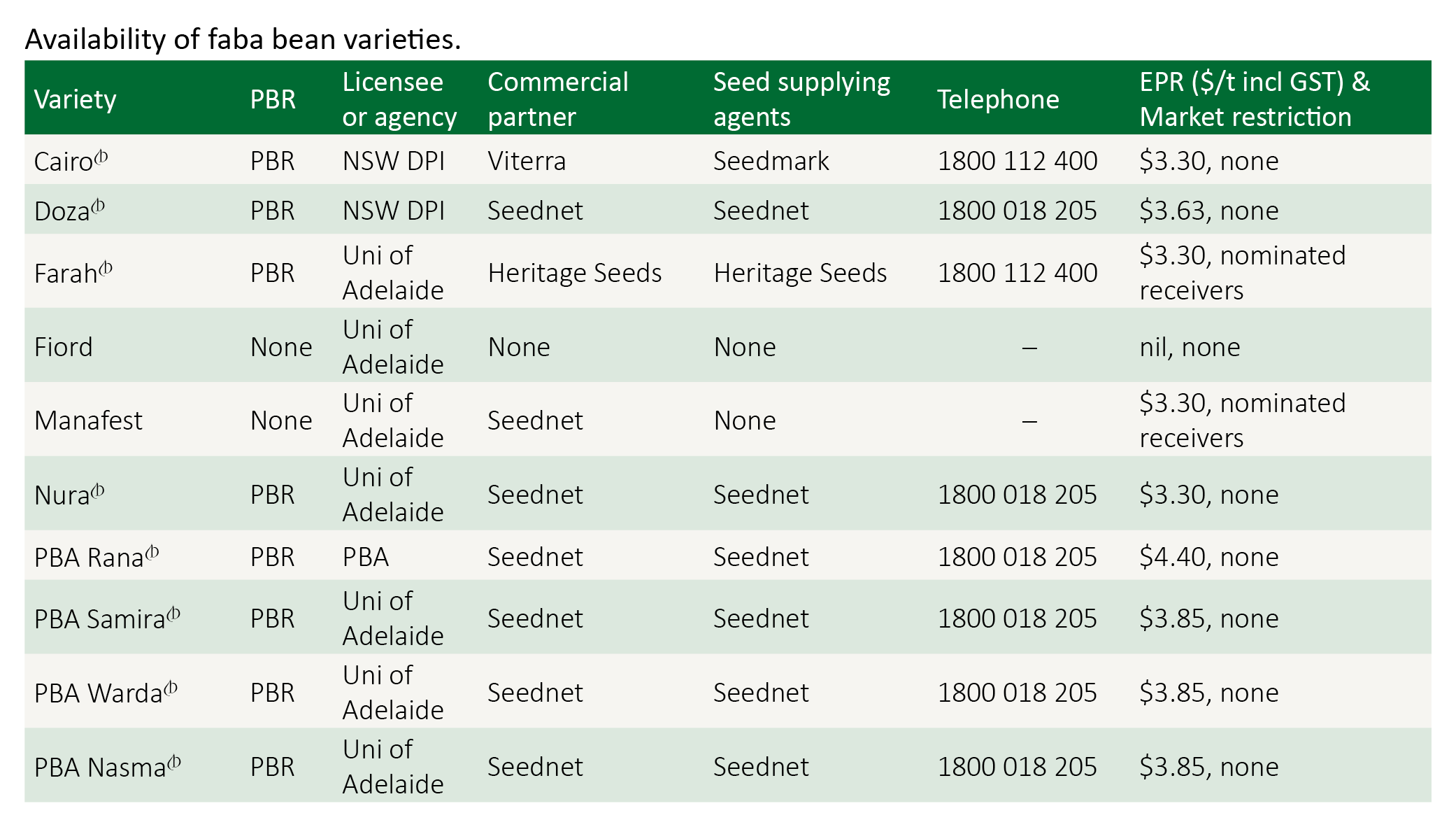

- Choose the right variety based on long term yield data for the region, maturity, disease resistance and market opportunities for either human consumption or stockfeed.

- Use good quality seed. Obtain certified seed, or keep good quality home-grown seed, with high germination (80%+) and vigour. Seed must be free from seed-borne ascochyta pathogens.

- Select and manage paddocks well in advance to control weeds and retain crop residues. Select paddocks with free draining soil of more neutral pH and low sodicity, salinity and boron toxicity. Take previous residual herbicide use into account and factor in the effect of the likely weed burden and the available control options.

- Establish optimum plant populations for the variety, situation and sowing time. Ideally ground cover should coincide with the beginning of pod filling. Plant populations can range from as few as 20 plants/m2 (even less with broad beans) up to 35 plants/m2 for rain-fed crops or even higher if sown late.

- Sow on time. Sowing time is critical so follow the regional recommendations. Late sowing lowers crop biomass, shortens the pod-filling period and increases the risks associated with moisture stress and high temperatures, all of which reduces yield potential.

- Ensure good crop nutrition. Well nodulated faba bean and broad bean plants do not require any nitrogen (N) fertiliser. Inoculate the seed at sowing with commercially available rhizobia inoculant to ensure effective nodulation. On phosphorus (P) deficient country, apply fertiliser at rates similar to or slightly above those required for wheat. On alkaline clay soils, application of zinc fertiliser may be warranted. Acid soils may be deficient in molybdenum, which should be applied at or before sowing if required.

- Know the disease threats to faba beans and how to manage them for your district. The major risks to faba bean are ascochyta blight, chocolate spot and plant viruses, and occasionally rust. No varieties are resistant to all fungal and virus diseases. The impact of fungal diseases on yield can be reduced through the strategic selection and use of fungicides and following best practice crop management including isolating new crops 500 m from the previous year’s faba bean stubble and eradicating volunteer plants over summer and autumn.

- Control insect pests. Use Gaucho® 350SD seed dressing and controlling any ‘green bridge’ over summer to deter aphids from infesting the crop in the early growth stages. Monitor for helicoverpa caterpillars that are likely to infest the crop and damage pods during pod-filling and may make the seed unsuitable for human consumption markets.

- Harvest on time, with a properly set-up header. Start when nearly all pods are black, but before stems become completely dry and black. If the header settings are correct, pods will thresh easily to yield clean, whole seeds with a minimum of splits and cracks.

- Have a marketing plan for on-farm storage or delivery options off-header, which may involve forward contracting if storage, pools or warehousing is not an option.

- Optimise irrigation set ups and timing. Faba beans respond well to irrigation in dry areas. Furrow irrigation is successful in southern irrigation areas with either pre-water and sow, or dry-sow and water-up. To maximise yield potential, crops should be watered to produce maximum biomass, and not allowed to stress during flowering and pod-fill.

Plant physiology

Faba bean plants stand erect and can grow to around 2 m at maturity, however most Australian crops are less than 1.5 m tall. They produce branches stemming from the base. Leaves are compound, with leaves from in the early growth stages having only 2 leaflets and leaves formed after the commencement of flowering have up to 7 leaflets per leaf.

The tap root penetrates to around 60 cm with a profusion of fibrous roots. Beans do however produce less roots and are shallower rooted than cereals.

Flowering in early varieties begins from about the 5–7th node (joint) in early maturing varieties and up to node 15 or higher in later maturing varieties. Flowers are in clusters (inflorescences) comprising 3–8 flowers (varying with variety) in the axil (angle between leaf and stem) at each node. Inflorescences form in succession up the stem as each new node is produced over a 6–10 week period, or about 15 flowering nodes. Like many legumes, excess flowers are produced and fewer than 15% will develop into viable pods.

Faba beans are predominantly self-pollinating, however feral bees and introducing hive bees can increase pollination rates and yields. A pollination service is not necessarily practical in many cases due to failure by bees to collect nectar from the tube like flowers. There is a need to distribute hives evenly within the crop and manage the bees by ensuring they do not make honey.

Flowering will finish when daylight temperatures approach 30°C, after which only a few leaf bearing nodes are produced.

Pods in a well-grown crop are borne from about 20–30 cm above ground level. Each pod contains 2–4 seeds, which will vary in size depending on variety.

Bottom pods will mature first and turn black, as will the bottom leaves. This will continue gradually upwards as the plant senesces.

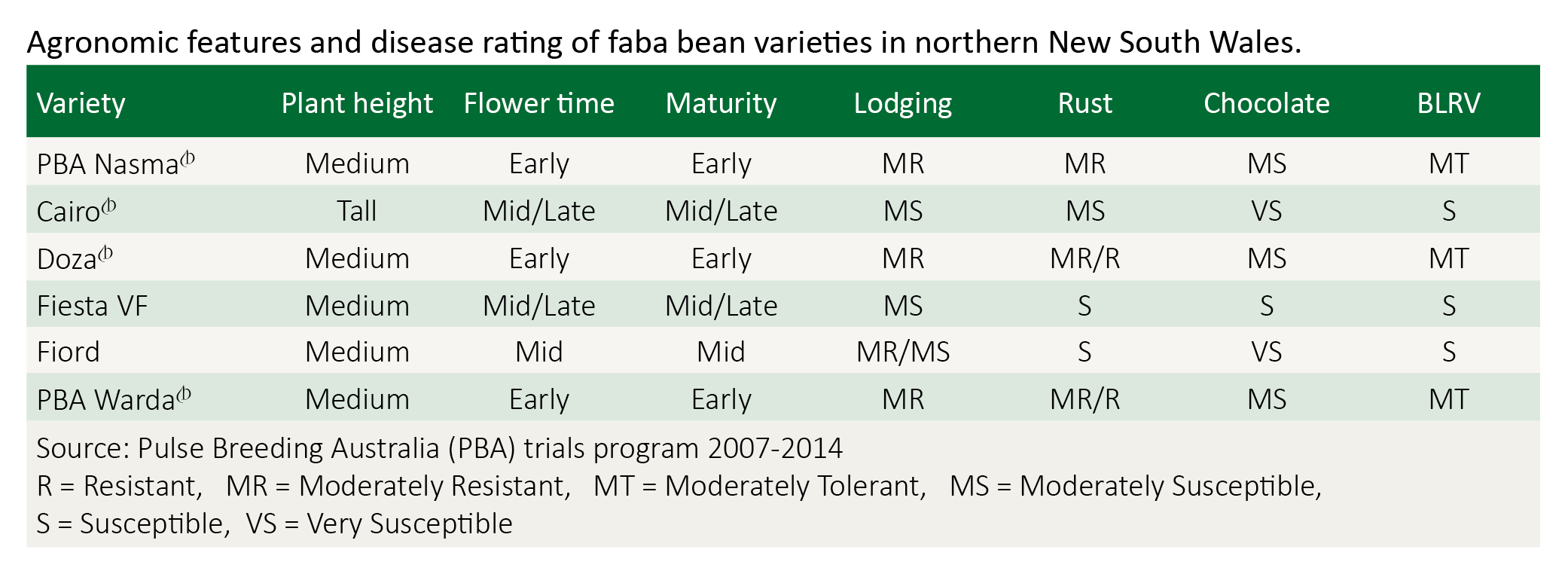

Variety selection

When selecting a variety, consider season length, seed size (with reference to available sowing machinery), disease tolerance, seed availability, yield potential, lodging resistance and target markets. Varietal resistance to chocolate spot (Botrytis fabae) is extremely important as this disease is a potential problem for faba and broad beans in higher rainfall areas, under irrigation and in wetter years. A strategic foliar fungicide program is essential in most areas. Improvement in varietal resistance continues to be a priority in the plant breeding program.

Ascochyta blight (Ascochyta fabae) in faba bean was once a serious limitation to faba bean production however, this disease is now largely avoided through the use of resistant varieties.

Some bean varieties available to growers have limitations in agronomic adaptation and marketability and will not suit all areas or situations.

When comparing yields between varieties, growers need to be aware that under high chocolate spot pressure or high moisture stress, varieties with greater susceptibility are more likely to suffer greater yield loss than the less susceptible varieties.

Faba and broad bean varieties are bred for and selected in a range of different environments. Hence individual varieties have specific areas of adaptation for maximised yield and reliability. Specific adaptation of a variety depends on rainfall, geography, temperatures, disease pressure and soil types of where it is grown.

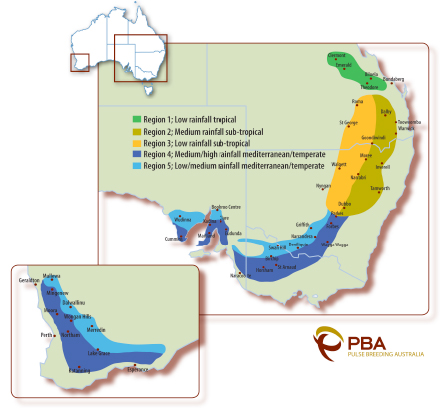

The national pulse production area has been categorised by Pulse Breeding Australia (PBA) into five regions based on rainfall and geographic location. Most faba bean varieties are adapted to Zones 4 and 5 however some newer varieties have been released that have adaptation to Zones 2 and 3.

Faba bean varieties

Cairo was released for the northern region, being superior to Fiord and Barkool for yield, seed size and quality. It also had better rust resistance and tolerance to stem collapse from frost. It is now superseded for yield and rust resistance by Doza and PBA Warda. Not generally recommended for southern regions where Ascochyta and chocolate spot are major problems. Released in 2004.

Area of Adaption: Zones 2 & 3 For more detailed information:

Doza is a medium sized faba bean released for the subtropical environments of northern NSW and southern Queensland. Early flowering enables it to better adapt to warmer spring temperatures, along with higher yielding and substantially improved rust resistance over Cairo. Seed size is slightly smaller but uniformity of seed size and a light buff seed coat is a significant improvement for this region. Doza has good resistance to stem collapse from frost which is an important trait in this environment. Doza has reasonable resistance to chocolate spot but is very susceptible to Ascochyta blight, and is not suited to southern Australia. Released in 2008.

Area of Adaption: Zones 2 & 3 For more detailed information:.

PBA Warda was released for the northern region being superior to Doza for yield, seed size and disease resistance. It replaces Doza and Cairo in the northern region.

PBA Warda is moderately resistant to resistant (MR–R) to rust, equivalent to Doza, and has a higher level of tolerance to bean leafroll virus (BLRV) than Doza. It has similar flowering and maturity time to Doza, but bigger and more uniform seed size. Released in 2012.

Area of Adaption: Zones 2 & 3 For more detailed information: PBA Warda Variety Management Package

PBA Nasma has a larger seed size than other varieties grown in the northern region. Its large and uniform seed size and bright colour makes it readily acceptable in the human consumption market of the Middle East. PBA Nasma produces medium sized beige to brown seeds that are approximately 15–20 per cent larger than PBA Warda. Seed colour changes during storage are similar to PBA Warda.

PBA Nasma equally well adapted to northern New South Wales, where it has out-yielded PBA Warda by 3 per cent in both rain fed and irrigated trials and offers a similar level of resistance to faba bean rust and tolerance to bean leaf roll virus (BLRV) as that of PBA Warda. Released 2015.

Area of Adaption: Zones 2 & 3 For more detailed information: PBA Nasma Variety Management Package

General agronomy

Paddock selection

New faba and broad bean crops should be separated from previous year’s crop stubble. Maintain a distance of at least 500 m, and up to 1 km in areas where old stubble is prone to movement i.e. down slope and on flood plains, to reduce the spread of ascochyta blight.

Avoid paddocks with high weed burdens because faba and broad beans do not compete well with weeds. Check herbicide use over the previous 12–24 months and assess any potential residue problems prior to sowing.

Check any soil tests and/or records, paying particular attention to the following soil characteristics:

- pH 5.2–8.0

- soil type – loams to self-mulching clays

- sodicity

- salinity/chloride

- bulk density

- potential for waterlogging

- amount of stored soil moisture and received rainfall, noting their potential impact on herbicide residues.

Residual herbicide

Residues of sulfonylurea herbicides can persist in some soils. These residues can last for several years, especially in more alkaline soils and where there is little summer rainfall. Faba beans sown in affected paddocks will emerge and grow normally for a few weeks and then start to show signs of stress. Leaves become off-colour, roots may be clubbed, the plants stop growing and eventually die. Beans and vetches are more sensitive than other pulses to Logran® than to Glean® residues. Faba beans are one of the least sensitive pulses to chlorsulfuron residues in soil. Refer to the labels for recommendations on plant-back periods for faba bean following use of any herbicides. Be especially wary in seasons where there has been limited rainfall since the herbicide was applied.

Picloram (e.g. Tordon® 75-D) residues from spot-spraying can stunt any pulse crop grown in that area. This damage is especially marked in faba beans where plants are twisted and leaves are shrunken. In more severe cases, bare areas are left in the crop where this herbicide has been used—in some cases more than five years previous. Although this damage is usually over a small area, correct identification of the problem avoids confusion and eliminates concern that it may be caused by disease.

In wheat–faba and broad bean rotations the use of fallow and in-crop residual herbicides such as Broadstrike®, Eclipse®, Flame®, Grazon®DS, Lontrel® and metsulfuron (Ally®, Associate®, Lynx®) and Harmony®M should all be avoided, particularly during the summer fallow or weed control period (after November).

The use of long-term residual SU herbicides such as Monza®, chlorsulfuron (Glean®, Lusta®), and Logran® in wheat should be avoided when re-cropping to faba and broad beans.

For more detailed information: Residual herbicides and weed control

Stubble retention

Presence of stubble can increase water infiltration and slow moisture loss through evaporation. With standing stubble, lower wind speeds at the soil surface and cooler soil temperatures assist in reducing evaporation, hence increasing soil moisture storage for sowing and afterwards. Winter crops in southern cropping areas are dependent on incident rainfall. Stubble retention ensures that more of that moisture is captured and retained as stored soil moisture. Stubble retention also helps to retain some of the deeper moisture left from summer rains, provided weeds are controlled.

The beneficial effect of stubble retention is most apparent in dry years. Retaining rather than burning stubble allows for earlier sowing due to the preservation of moisture near the soil surface.

Stubble bunching or clumping can occur when sowing into retained stubble. These mounds of stubble are often picked up in the header front, causing mechanical blockages and contamination of the sample if they contain excessive amounts of soil. To avoid stubble clumping:

- use a zero-till (disc) seeder, or other seeder capable of handling heavy stubble

- modify existing air-seeders (tine shape and lifting some tines)

- sow before soil and stubble becomes too wet

- use rotary harrows to spread and level stubble.

Standing stubble can be slashed or burnt if sowing equipment with good trash flow is not available.

For more detailed information: Wide row and stubble management

Paddock preparation

Aim to direct drill faba and broad beans into standing cereal stubble. Crops reliably yield 10% higher when established this way.

Uniformity of soil type, paddock topography, and surface condition of the paddock are all important criteria in assessing whether country is suitable for faba and broad bean production.

Harvest losses are much higher in rough or uneven paddocks, particularly in dry seasons when crop height is reduced. Sticks or rocks, eroded gullies or gilgais (‘melon’ or ‘crab’ holes) will prevent headers operating at low cutting height. The smoother the land surface the better, particularly when using headers with wide fronts. Small variations in paddock topography can lead to big variations in cutting height across a wide front and a subsequent increase in harvest losses.

If growing irrigated faba and broad bean then select fields with good irrigation layout and tail water drainage. Beds or hills are preferred if flood irrigating, however border-check layout has been successful with grades steeper than 1:800 or with short runs that can be watered quickly (< 8 hr). Waterlogging is most detrimental if it occurs after flowering so where possible avoid border-check irrigation once flowering has commenced. Late irrigation of faba beans on beds and hills are and sprinkler irrigation is generally safe.

Broad bean, and to some degree faba bean, crops can be quite indeterminate in the southern environment and moisture supply strongly influences crop maturity. Changes in soil type and moisture holding capacity across a paddock can lead to uneven crop maturation, delayed harvesting and increased risk of weather damage or high harvest losses. Paddocks that have even soil types are relatively easier to manage, and are preferred for faba and broad beans.

Inoculation

Faba and broad beans have the ability to ‘fix’ their own nitrogen from the air via nodules on their roots if specific nitrogen fixing bacteria (rhizobia) are available.

The strain of rhizobia used for faba and broad beans is highly specific (Group F - WSM1455). Unless the right strain is present in the soil or has been supplied by adding a commercial inoculant at seeding time, effective root nodulation will not take place and little if any nitrogen will be fixed. These effects are not always immediately obvious above ground and are not easily remediated.

For more detailed information: Inoculation of pulses

Sowing

High quality seed is essential to ensure the best start for your crop. Grower retained seed may be of poor quality with reduced germination and vigour, as well as potentially being infected with seed-borne pathogens.

- All seed should be tested for quality including germination and vigour.

- If grower retained seed is of low quality then consider purchasing registered or certified seed from a commercial supplier and always ask for a copy of the germination report.

- Regardless of the source, treat seed with a thiram-based fungicide.

- Careful attention should be paid to the harvest, storage and handling of grower retained seed intended for sowing.

- Calculate seeding rates in accordance with seed quality (germination, vigour and seed size).

For more detailed information: Pulses: Inoculation and Chickpea: High Quality Seed

Seed treatment

Seed treatment is very effective against seed rot, but is not commonly used in faba and broad bean. If the seed is treated, it should be planted immediately after inoculation, as seed treatments can be toxic to the inoculant. The longer the inoculant is in contact with the seed treatment, the less effective the inoculant will be.

Seed testing

Check details

Sowing rate

Target plant populations of 30 plants/m2. Seeding rates (kg/ha) for faba and broad beans will vary with the size of the seed being sown. For example, a sowing rate of 150–200 kg/ha for Fiesta, Farah or Nura with an 85% germination test, but only 100–160 kg/ha of a smaller-seeded variety like Fiord.

The plant density of broad beans need to be reduced to as low as 10–15 plants/m2 as they are grown in areas with long, cool growing seasons. This will reduce the seed cost per hectare, reduce the density of the crop and help reduce the risk of foliar disease.

All seeds are not equal, some grow better than others. Before deciding on a seeding rate take a representative sample, have it sized and then germination and vigour tested.

Seeding rates can have a very significant effect on crop yields. Be aware of the very large difference in seed size between individual varieties and the impact that variable seasons can have on grain size. Adjust the kilogram rate to achieve a target population of plants based on seed size and germination percentage.

Sowing depth

Vary sowing depth to take into account of soil type, herbicide used, diseases likely to be present and soil temperature at sowing time. Faba bean seed is usually sown at a depth of 5–8 cm. Lighter textured soils can be more prone to herbicide leaching in wet winters, hence deeper sowing in sandier soils is often recommended if applying a pre-emergent herbicide. The deepest sowings tend to be in sandy soil with warm soil temperatures and if dry sowing. The shallowest sowings will be in heavy soils with cold soil temperatures or late sowing, however there are exceptions.

For more detailed information: Chickpea: Deep seeding

Row spacing

There is a trend towards wider row spacing with pulses, especially faba and broad beans. Wider row and ’skip’ row pulses (30–54 cm) must be part of an overall system and should not be considered in isolation. Stubble retention, preferably standing stubble, to retain soil moisture and ensuring adequate weed control is considered essential with wide rows. Yield comparisons in research trials vary depending on the system and location, demonstrating that row width alone does not guarantee a particular yield response.

Wider rows configurations can provide some or all of the following benefits:

- higher or more consistent yield

- better stubble clearance and ease of sowing

- improved water use efficiency and drought tolerance

- reduced risk and ease of applying fungicide sprays

- spread machinery and labour pressure over a longer period

- less weed germination due to reduced soil disturbance

- inter-row herbicide application becomes an option.

If row spacing is doubled, the seeding rate per row must be doubled to maintain the same plant density. This is significant for seeders with one seed meter per row, but relatively unimportant in air seeders where one meter supplies all or part of the machine. Be aware of changes needed for seeding rate calibrations.

The same considerations apply for fertiliser rates, but remember also that the risk of toxicity to seed increases when fertiliser is more concentrated in the seeding furrow. Sowing pulses into wider rows may require deep placement or side banding of the fertiliser.

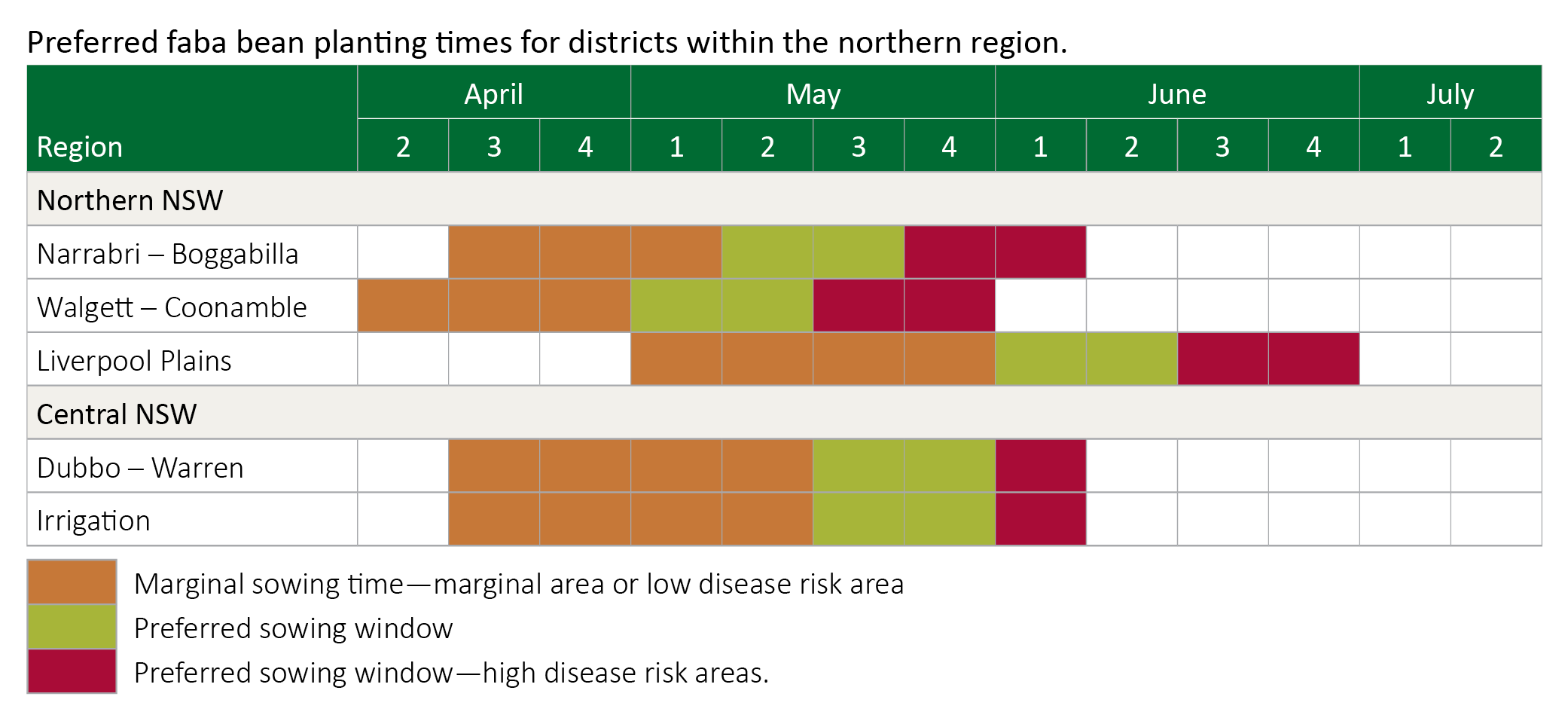

Sowing time

Faba bean sowing dates are often a compromise between delaying sowing to reduce disease risk while sowing early enough to maximise yield potential. Early sowing, even dry sowing, is a priority in some drier areas or where sowing is completed early to optimise operations and enable optimum sowing times for cereals.

Most faba and broad bean varieties are either susceptible or moderately susceptible to chocolate spot (Botrytis fabae), meaning that sowing times in southern Australia may still need to be delayed in some circumstances to reduce the risk of chocolate spot infection. This consideration no longer applies regarding ascochyta risk as most new faba and broad bean varieties are either resistant or moderately resistant to ascochyta blight.

Delayed sowing can help avoid frost or cold conditions during flowering, particularly in areas with long growing seasons.

Faba and broad bean show a marked response to time of sowing, with crops sown ‘on time’ having an excellent chance of producing very high yields. However, crops sown earlier or later than recommended will often suffer from reduced yields. Water use efficiency is commonly in the range of 8–12 kg grain/ha/mm for sowings made during the preferred sowing window. This drops away to 4–6 kg/mm for very late or very early sowings.

Sowings made prior to the recommended sowing window tend to be more vegetative and suffer from:

- poor early pod set because of low light or low temperatures (10°C) at flowering commencement

- higher risk of chocolate spot at flowering and through podding

- being more pre-disposed to lodging

- increased frost risk at flowering and early podding

- high water use prior to effective flowering and the earlier onset of moisture stress during flowering and podding

- increased risk of ascochyta blight in susceptible varieties.

Late planted crops are more likely to suffer from:

- high temperatures and moisture stress during flowering and podding

- greater native budworm pressure

- less branching and flowering sites, unless plant population is increased.

- shorter plants and lower pod set, making harvest more difficult.

To achieve maximum yields critical management factors such as weed control and seed bed preparation must be planned to allow crops to be sown as close as possible to the ‘ideal sowing dates’.

Faba and broad bean seed can germinate in soil as cold as even 5°C, but emergence will be slow. Seedling vigour will be greater if soil temperatures are at least 7°C. Faba and broad bean seedlings are tolerant of frost.

Dry sowing

Dry sowing while awaiting a germinating rain can fit in well with the sowing program for faba and broad bean, there are a number of factors to consider before choosing this option, such as the:

- weed seed burden and the weed control options available

- need for the rhizobia to survive in dry soil, particularly if the soil is acidic

- type of soil and the ease of sowing into that soil when it is dry (including uniformity of sowing depth, soil tilth etc.)

- ability to enter the paddock after rain to perform activities such as harrowing, rolling and spraying pre-emergent herbicides) in a timely manner

- clodiness of the soil after sowing and the impact of this on herbicide application and harvest operations

- need for additional levelling to flatten any ridges, cover press wheel furrows or flatten clods.

Rolling

A flat soil surface at harvest becomes even more important when crops are short at maturity or are tall but have lodged. Rolling after sowing to aid harvestability when the bottom pods are close to the ground as often occurs in lower rainfall areas or late sown crops.

Another reason for rolling is to leave a flat soil surface for to prevent herbicides washing into and accumulating in furrows following post sowing herbicide application. Rolling also improves seed soil contact in sandy non-wetting soils, although press wheels on the planter will normally achieve adequate seed-to-soil contact.

Faba and broad beans can be rolled post-emergent if the plants themselves are not taking the weight of the roller, but generally early after emergence would be the preferred timing. However, there is a greater risk of foliar disease if beans are rolled post-emergence.

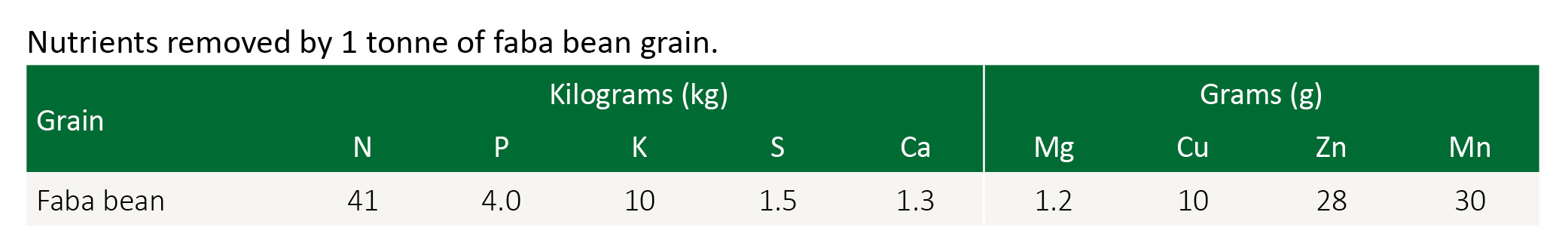

Nutrition

Nitrogen

Faba and broad beans should not normally need nitrogen fertiliser, provided that plants have effectively nodulated. For further detailed information: Pulses: Inoculation

The first sign of nitrogen deficiency in faba bean is a general paleness of the whole plant, even before a general reduction in plant growth. There may be a cupping of new leaves. Over time a mottled chlorosis of old leaves slowly develops with little sign of necrosis.

Check for nodulation and determine if the nodules are actively fixing nitrogen.

Phosphorus

Faba beans are considered very responsive to phosphorus fertiliser, but zinc status must be adequate to achieve a P response.

Potassium

Older leaflets show symptoms first, and initially growth is stunted compared with other parts of the paddock, e.g. in old stubble rows. Older leaves show a slight curling and then a distinct greying of leaf margins, eventually dying.

Sulfur

Symptoms of sulfur deficiency include the youngest leaves turning yellow and plants are slender and small. Certain soil types are prone to sulfur deficiency, e.g. some basaltic, black earths. Soil sampling to a depth of 60 cm is the recommended to test for sulfur.

Zinc

Faba beans are considered very responsive to zinc fertiliser, but phosphorus status must be adequate to achieve a response to zinc. Symptoms of zinc deficiency include stunted growth and the lower leaves develop yellowing between the leaf veins. Maturity can be delayed.

Faba and broad beans are considered to have a relatively high demand for zinc and have highly efficient mechanisms for extracting Zn from the soil. Foliar application of zinc is relatively common, often fitting in with herbicide or early fungicide applications.

Arbuscular mycorrhizae (AM) can be extremely important to phosphorus and zinc nutrition in faba and broad beans, and responses can be expected in situations where AM levels have become depleted due to long fallows (over 8–10 months).

Irrigation

Full and supplementary irrigation of faba and broad bean is practiced in Australia where it is economical in rotation with other winter and summer crops. Management requirements for irrigated faba and broad bean are generally the same as for dryland crops. The additional risk of foliar disease under irrigation must be taken into account along with the risks associated with waterlogging, particularly after the commencement of flowering.

There are a number of factors to consider when choosing irrigated faba and broad bean production, including:

- avoiding heavy clay or dense soil types (bulk density >1.5) and paddocks that do not drain freely and are subject to waterlogging,

- selecting fields with suitable irrigation layout (e.g. beds or hills) and sufficient grade to allow adequate drainage. A border-check layout steeper than 1:800 grade is suitable provided there are short runs and free draining soils,

- rolling to flatten the ridges left by press wheel furrows or to flatten clods,

- using irrigation to activate and incorporate certain pre-emergent herbicides.

Irrigation scheduling

- Pre-irrigate to fill the moisture profile prior to planting faba and broad bean crops unless there has been sufficient rainfall. Pre-irrigation is not recommended for a border-check layout unless moisture is insufficient to achieve a uniform germination.

- As a general rule, in crop irrigation should start when there is a deficit of between 30–40 mm and around 60–70% field capacity. Moisture scheduling is more important than growth stage.

- Ensure ample moisture is available prior to the commencement of flowering to prevent moisture stress and high temperatures impacting on yield, quality and grain size.

- For furrow irrigation, water every second row to avoid waterlogging. Doubling up siphons can increase water flow and reduce irrigation time.

- Aim to have watering completed in less than eight hours, and have good tail water drainage to avoid waterlogging in the crop area.

- Do not irrigate if there is a reasonable likelihood of rain soon after.

- Faba and broad bean are more sensitive to waterlogging during their reproductive stage (flowering and podding). If in doubt, do not water.

- Sprinkler irrigation is ideal to minimise waterlogging, however there may be a need for greater disease control against chocolate spot, rust or ascochyta blight due to more frequent wet conditions.

Note that faba bean is one of the more sensitive field crops to salinity, but not as sensitive as field beans (Phaseolus vulgaris).

Weed management

Growing faba and broad bean in the crop rotation can assist in weed control when sowing is delayed sowing in higher rainfall areas, providing an opportunity for knockdown weed control before sowing. Faba and broad beans can also be grown in wider rows in a stubble system that allows inter-row herbicide application with shielded sprayers.

If sowing is done into dry soil, there is a delay (14–28 days) before beans emerge after germinating rains, allowing a non-selective knockdown herbicide application to kill emerged weeds just prior to the beans emerging.

Faba and broad beans do not compete well with weeds during the early crop growth phases in southern Australia because of the crop is slow to germinate, plant population is relatively low and there is an extended period before canopy closure.

Croptopping is not possible or safe in broad beans, and may not be timely or fully effective in faba bean varieties without affecting either crop yield and quality or the efficacy of preventing seed set of ryegrass.

Problem weeds in faba and broad beans that require special attention or are difficult to fully control include:

- Annual ryegrass that is resistant to group A products (‘dims’ and ‘fops’), particularly where high rates of clethodim are required.

- Annual ryegrass that is resistant to trifluralin.

- Snail and other medic.

- Wild radish—there are no safe treatments available post-emergent.

- Hoary cress, soursob and tares.

For further detailed information: Pulses: Residual herbicides and weed control and Pulses: Desiccation and croptopping

Avoiding herbicide damage

Some herbicides can severely damage chickpea crops through residues in soil, contaminants in spray equipment, spray drift onto the crop or by incorrect use of the herbicide.

The importance of cleaning and decontaminating spray equipment before the application of herbicides cannot be over-stressed. Traces of sulfonylurea herbicides (such as chlorsulfuron, metsulfuron or triasulfuron) in spray equipment can cause severe damage to chickpea and other legumes when activated by grass control herbicides.

Pulse crops can be severely damaged by some hormone herbicide sprays, such as 2,4-D ester, drifting into the crop. This can happen when these sprays are applied nearby in very windy or still conditions, especially where there is an inversion layer of air on a cool morning.

Taking some general precautions can help to reduce the likelihood of crop damage with residual herbicide use at planting:

- Do not apply residual herbicides if rain is imminent.

- Maintain at least 7.5–10 cm soil coverage.

- Avoid leaving a furrow or depression above the seed that could allow water (and chemical) to concentrate around the seed or seedling.

- Avoid leaving an exposed, open slot over the seed with disc-openers and avoid a cloddy, rough tilth with tined-openers.

For descriptions and pictures of herbicide injury refer to ‘Field crop herbicide injury: The Ute Guide’ and ‘Chickpea Disorders: The Ute Guide’ both are available from GRDC Groundcover direct.

Herbicide options

Faba and broad bean varieties do differ in their herbicide tolerance, depending on season, soil type and rate of application. Herbicide labels generally do not reflect these subtleties.

PBA Rana shows similar performance to all current varieties of faba beans at label recommended rates of registered herbicides based on visual observations from NVT and PBA breeding trials conducted on a range of soil types.

Herbicide tolerance trials in South Australia (alkaline sandy loam soils) show that herbicides commonly used in faba bean can be used with some degree of safety. Nura has exhibited greater sensitivity to imazathapyr (e.g. Spinnaker®) in some herbicide tolerance trials in South Australia. All varieties do exhibit some yield loss to imazathapyr.

In South Australian herbicide tolerance trials (2000–2010) as reported by NVT, Simazine applied post emergence can be more damaging than when applied PSPE, especially with the variety Farah. Simazine has a narrow safety margin and some yield loss (up to 21%) can be expected at standard rates.

Raptor® (imazamox) has a narrow safety margin in all faba bean varieties. It can be applied under APVMA permit. Field experience is that damage is more severe under moisture stress and conditions of slow growth. It should be considered a salvage option rather than a routine application.

Diuron has been safe in Farah and Nura over 7–8 trials, but check current registration status with broadacre crops.

PBA Kareema and Aquadulce broad beans shows similar performance to all current varieties of faba beans at label recommended rates of registered herbicides based on visual observations from PBA breeding trials conducted in high rainfall areas.

Severe seasonal effects on herbicide activity occur, so work is ongoing to validate findings under differing seasonal conditions. Review the relevant Variety Management Package.

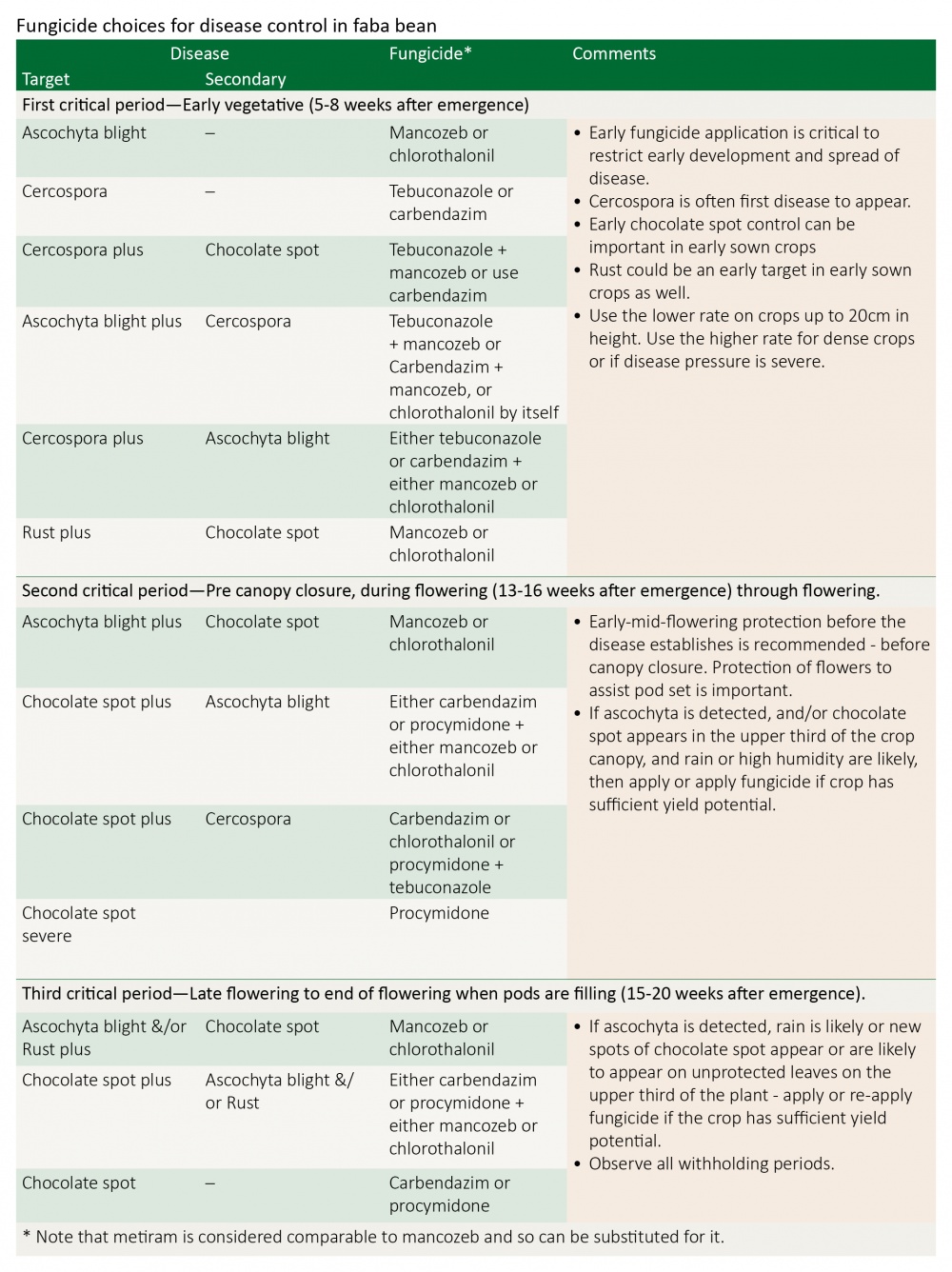

Disease management

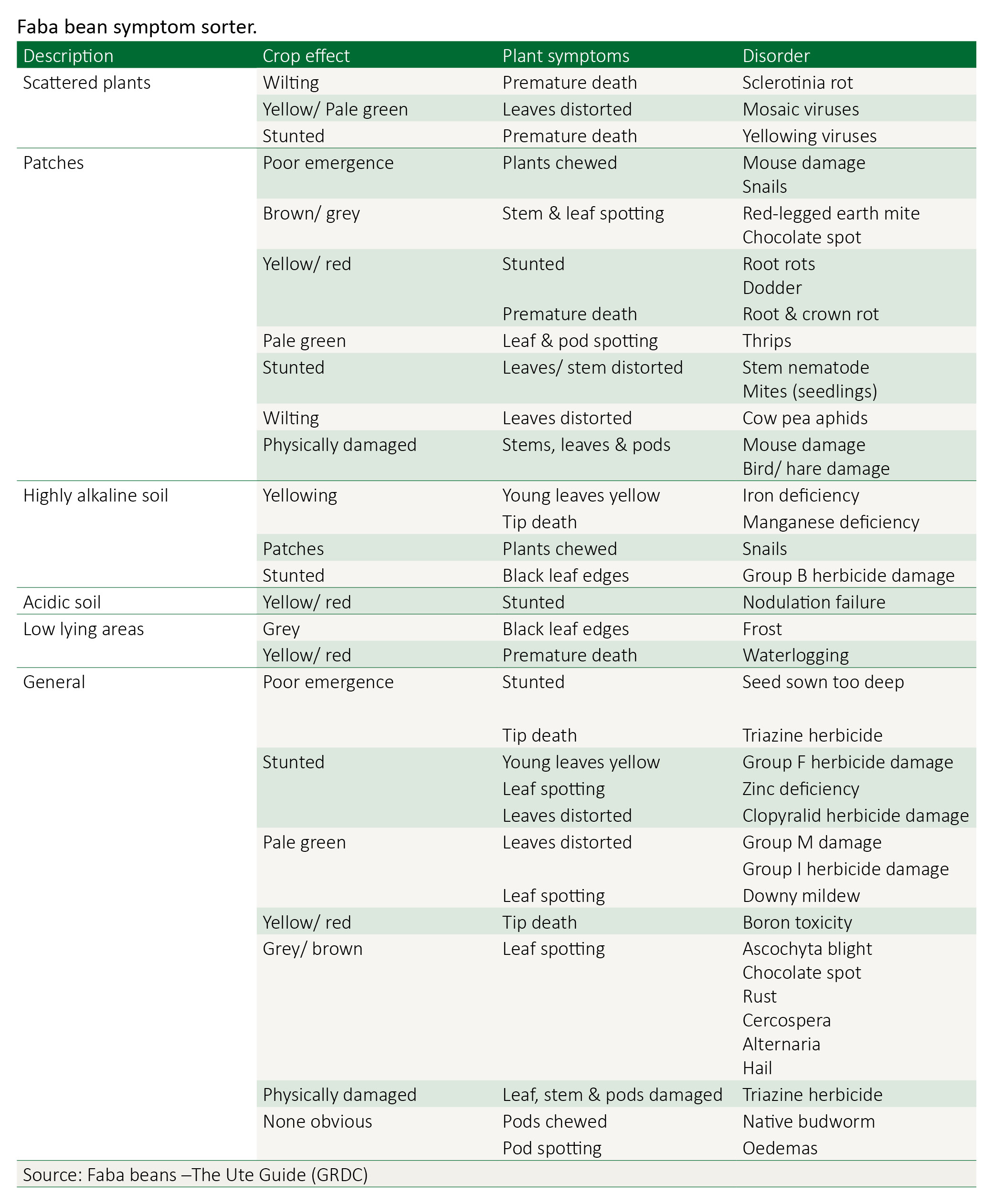

The four main diseases in faba and broad bean that require monitoring are chocolate spot (Botrytis fabae), ascochyta blight, cercospora (Cercospora zonata) and rust (Uromyces fabae). By following the monitoring process recommended for these diseases, there is the opportunity to assess the impact or presence of other diseases, weeds or plant disorders. To be effective, crop monitoring needs to include a range of locations in the paddock, preferably following a ‘V’ or ‘W’ pattern.

Ascochyta blight

The initial symptoms will be lesions on the leaves and stems of young plants. A distinguishing feature is fungal fruiting structures (small black dots) visible within the centre of lesions.

Monitoring should commence 2–3 weeks after emergence, or 10–14 days after a rain event. This is to allow time for disease expression after an infection event, such as transmission from infected seed or rain-splashed inoculum. Infected seedlings may deteriorate quickly and affected plant parts above the lesion may break off, making symptoms difficult to detect.

Timing is critical! After the initial inspection, subsequent inspections should occur every 10–14 days after a rain or heavy dew event. During dry periods, inspections can be less frequent. When monitoring, look for signs of lesions on leaves, or if severe, wilting in upper foliage or small areas of dead or dying plants, and if present examine individual affected plants for symptoms of infection. This method will allow more of the crop to be inspected than a plant-by-plant check.

Chocolate spot

Chocolate spot is more likely to occur in bulky crops after canopy closure. The critical stage for the first inspection will be just before the commencement of flowering, as temperatures begin to increase, and then regularly through the flowering and seed filling period. Lesions occur on leaves and flowers first, but can occur on stems and pods. Flower abortion and drop can occur.

Symptoms first appear as small brown spots on leaves and flowers, which then rapidly develop into large irregular shaped lesions on leaves and decay of flowers if conditions remain favourable.

Chocolate spot (Botrytis fabae) requires high leaf moisture or humidity (>70%) within the crop canopy and optimal temperatures are 15–28°C. When humidity levels decrease or maximum daily temperature exceed approximately 28°C, the infection levels decline sharply.

More regular crop monitoring and protection may also be required in high risk situations such as:

- immediately adjacent to last year’s crop

- non-optimal paddock selection (e.g. waterlogging)

- high disease pressure in the previous season

- susceptible variety sown

- short rotation.

Cercospora

Cercospora monitoring must start 2–3 weeks after emergence, or within 4–6 weeks of sowing. This is particularly important where faba beans have been grown in the paddock in recent years or there has been quite a few beans grown in that paddock over time.

Protective fungicide needs to be applied before or at first signs of cercospora lesions, or within the monitoring timeline, irrespective of symptoms when disease risk is high.

Subsequent monitoring should occur when checking for chocolate spot prior to and during flowering and podding.

Rust

The time to start monitoring for rust in faba and broad beans in southern Australia depends on sowing time and presence of infection on bean stubbles from the previous year.

With early sown beans, infection can occur at early emergence when temperature and rainfall conditions are suitable for its spread. Later sown beans may not get infected until spring, when temperatures, moisture and humidity are high.

Monitoring for rust needs to occur when monitoring for chocolate spot and late ascochyta.

For more detailed information: Faba bean: Integrated disease management

Problem solver

Pest management

Faba and broad bean are susceptible to attack from establishment pests such as redlegged earthmite, lucerne flea, cutworm, aphids and pasture looper, however their large leaves and early plant vigour makes faba bean less susceptible than some other pulses

The main insect pest of faba and broad bean late in the season in southern and Western Australia is the larvae of native budworm (Helicoverpa). It is important to be able to identify the different larval instars (very small, small, small-medium, medium-large, large) of Helicoverpa. Note that Helicoverpa punctigera is NOT the same species as H.armigera (commonly known as corn earworm or cotton bollworm), which is a major pest of chickpea and other pulses in northern Australia.

While snail populations do not build up as readily under faba bean as under field pea, they can still be a problem. Snails climb onto standing bean plants and even on standing cereal stubble in a stubble retention system. They can enter the grain sample at harvest with or without having climbed onto the faba bean plant.

For more detailed information:

Desiccation, harvest and storage

Early harvest of pulses is critical because delays can result in significant yield losses due to lodging, shattering and pod loss. Grain quality can also suffer through mechanical damage or weathering and seed staining. Moisture levels at harvest affect the quality of the grain in storage.

If harvesting grain for seed, germination rates are improved if grain is harvested at 12–14% moisture and then stored in aerated silos or immediately graded and bagged. Croptopping with herbicides prior to crop maturity may reduce grain quality and seed germination so should not be used in areas intended for seed production.

Harvest delays in faba and broad bean cost growers and the pulse industry a lot of money. In any production area it is not unusual to see up to a 4–6 week spread in the harvesting of faba and broad bean crops planted on the same sowing rain. Many late harvested crops are often as low as 8% moisture content, whereas the maximum moisture content for receival is 14% and preference is for 12%. Yield losses increase significantly the longer harvest is delayed.

While they are not normally prone to pod splitting and shelling out except in extreme wet weather conditions, faba and broad beans are very prone to pod splitting and pod drop after weather events once the plant has dried down. Weathering of the grain can also occur in split pods. Yield losses of up to 30% have been recorded in the field, due mainly to pod loss at the header front, or as un-threshed pods lost out the back of the machine.

Lodging can increase the longer faba and broad beans are left standing, and the risk is higher if the crop is high yielding and has been planted on wide rows.

Grain quality deteriorates the longer mature faba and broad beans are left exposed to weathering in the field. The seed coat of faba and broad bean is very prone to cracking if it has been exposed to wetting and drying events due to rain or heavy dew. Expansion of the seed as it absorbs moisture, and then contraction as it dries, weakens the seed coat. This renders it much more susceptible to mechanical damage during harvest and handling operations. Levels of cracked and damaged grain can be as high as 50% in extreme cases of field weathering and prolonged rainfall.

Faba and broad bean seed coats discolour and darken when exposed to field weathering, due to the oxidation of polyphenol compounds (tannins), making them less acceptable in the market.

The main reasons (or perceptions) influencing a grower’s decision to delay faba and broad bean harvest is usually based on:

- Faba and broad bean harvest can clash with cereal harvest. Faba and broad bean is still considered 'secondary' by some, with wheat or barley taking precedence at harvest time.

- The possibility of achieving premiums for PH/AH wheat or malting for barley is also a major incentive for prioritising the cereal harvest, although in reality the premiums for early harvested faba and broad bean are often greater.

- The perception that faba and broad beans 'weather' reasonably well, however this is a fallacy.

- Uneven ripening of faba and broad bean crops if not desiccated or windrowed, especially when grown on heavy clay soils or variable soil types.

- Faba and broad beans are considered slower or more difficult to harvest. This does not have to be the case if desiccation is used, and the header is modified to suit the crop.

Faba and broad bean is the most profitable winter crop for an increasing number of growers, as we see a more professional approach to production and marketing, rather than treating it as a minor, secondary crop where it is 'planted last, harvested last, and sold to the nearest buyer'.

For more detailed information: Faba bean: High quality markets

Implementing early harvest management

There are a range of management components that contribute to an early matured crop, and all can be important at different times and for different reasons. It is important to understand the potential and limitations of each component. Optimal results, in terms of yield, profit and earliness will be due to these components being applied in the most appropriate and balanced way, and as dictated by seasonal conditions at the time.

These components include:

Sowing

- Sow at the earliest opportunity but within the preferred planting window for your area. This may involve dry sowing by a particular calendar date.

- Moisture seeking equipment and/or press wheels can significantly enhance seeding opportunities under marginal soil moisture conditions.

- Use adapted varieties that meet your target for early harvesting.

- Using precision planters or machines with automatic depth control will often achieve more uniform plant establishment and crop development, and consequently more even crop maturity. This is particularly so when sowing into marginal soil moisture and drying conditions.

In-crop management

- Control of Botrytis grey mould if present during flowering.

- Control of native budworm during flowering to maximise early pod set.

- Avoid using herbicides that delay crop maturity, e.g. flumetsulam (i.e. Broadstrike®).

Harvest management

- Consider windrowing to enable earlier maturity and harvest date.

- Consider using a desiccant to dry late plants and any weeds.

- If using Glyphosate, (or equivalent registered products) to terminate crop growth at the 80 - 90% black-brown pod stage, be aware of potential impacts on seed quality.

- Set up the header to operate efficiently at 14 - 15% grain moisture content.

- A major advantage of high moisture harvesting is that harvest can commence earlier in the season and earlier each day. Harvesting at 14% moisture content as compared to 12% can effectively double the harvest period available on any one day in hot environments.

- Blend, aerate and/or dry the sample to the required receival standard of 14% moisture.

Desiccation

Faba and broad bean can be desiccated pre-harvest to enable earlier harvest and to dry out green weeds. Timing is based on crop stage, and is either similar to or later than that for windrowing depending on the product used.

The danger of premature desiccation is in causing staining of the seed coat, having excessive green cotyledons in the sample or producing small or wrinkled seed which can all create marketability problems.

In faba and broad bean, desiccation can occur when seed from the top of the plant has a black scar (hilum) and the lower 25% of pods are black. At this stage the upper pods are still bright green, but the lowest pods are starting to turn black and have seeds with a completely black hilum. DO NOT use Glyphosate to desiccate beans if the seed is to be retained for sowing.

For more detailed information: Pulses: Desiccation and croptopping

Windrowing

Windrowing of faba bean has become common in some areas as growers try to reduce problems associated with direct heading, uneven crop maturity or weed seed management. It is primarily to bring harvest date forward, uniformly ripen the crop, and protect the crop from shattering where harvest is to be delayed, or be a part of general management to reduce seed set of weeds present.

Windrowing faba bean crops provides a number of benefits:

- Uniform maturity of the crop in paddocks ripening unevenly

- Problems caused by late maturing weeds are avoided. These include delayed harvest which increases the risk of staining caused by the weather and disease, and storage problems from green weed contamination.

- Can advance harvest date when done as soon as the crop is mature, avoiding clashes with other crops, such as cereals (see Error! Reference source not found.).

- Weed seed is moved into a windrow that can be burnt after harvest.

- Low pods are harvested rather than being left behind, due to the lower cutting height possible with a windrower.

- Excessively tall crops can be better handled at harvest. When direct heading tall crops the reel can be in the way, pushing plants forward, causing problems with feeding material into the header and losses on the cutter bar. Direct heading very tall and lodged crops is also very slow. Windrowing can dramatically increase header efficiency.

- Windrowing reduces damage to headers. Headers working in rougher country can damage knife fingers and sections, retractable fingers and other components on sticks and stones. Pick-up fronts leave most of these on the ground.

Windrowing should only be used if direct heading the faba bean crop is likely to be a problem, and should not be considered a necessary operation every year. There are several risks to windrowing crops:

- Windrowing too early (prior to crop maturity) can cause significant yield and quality losses. Small and shriveled seed will result from drying down of immature seed.

- Windrowing too late can cause shatter losses as the cutter bar hits the crop.

- The seed coat can discolour if left too long in the windrow, especially in wet conditions when mould growth and seed staining can occur.

Timing of windrowing is critical and should be based on seed maturity rather than measurements such as leaf colour and drop, or pod colour, as these can be misleading. Leaves can be prematurely lost and pods blemished by disease. Faba bean seed is considered physiologically mature when you can see a black line on the hilum – a scar-like area on the seed where it attaches to the pod (Error! Reference source not found.).

The cutting height for windrowing should be just below the bottom pods with the reel following the top of the crop. The reel speed should be quite slow. The delivery opening in the windrower should be large enough to prevent blockages or there will be lumps in the windrow. Windrows should be dense and tightly knit for best results.

Curing should take about 10–12 hot days. However, heavy infestations of radish and other weeds can delay drying.

Pick-up fronts are the most common type used for harvesting windrows. However, crop lifters used close together on open fronts have been used with some success.

Harvesting

Take extra care, when harvesting pulses for seed, to reduce grain cracking even if this means making a poor sample. Gentle harvesting will give the best seed quality. Rotary harvesters are gentler on the crop and will generally cause less grain damage than conventional harvesters.

Faba and broad bean can be harvested with minor adjustments and modifications. Open-front or pick-up fronts are best suited to the job.

Faba and broad bean should be harvested as soon as they mature as pods will fall if harvest is delayed.

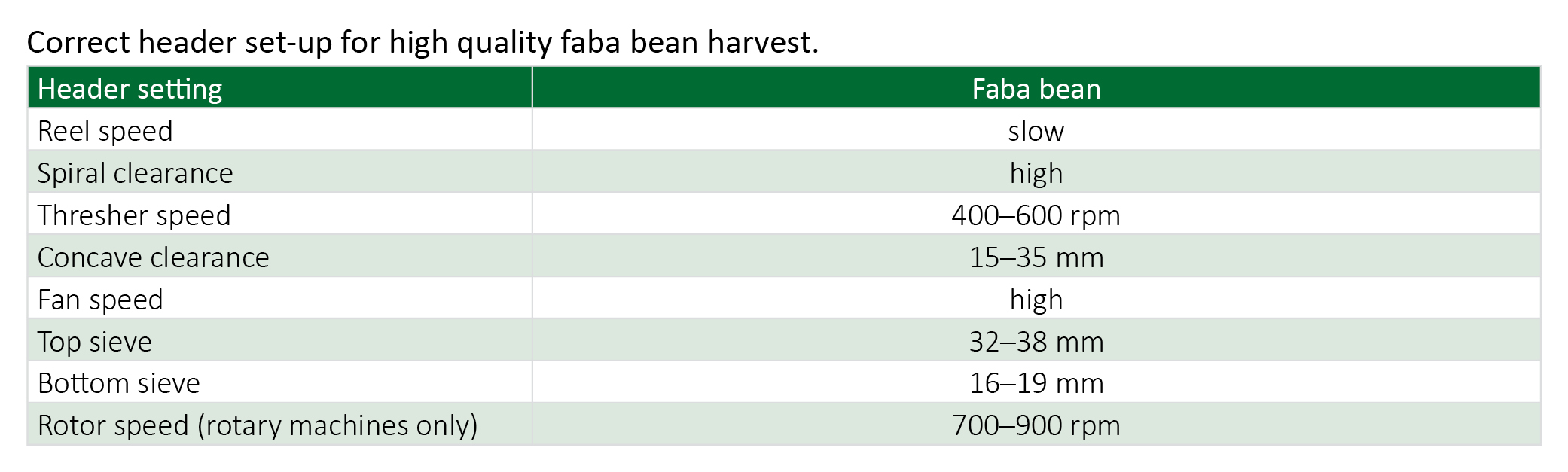

The crop varies in height from 15–80 cm with pods held up in the canopy so direct heading without crop lifters is possible with open front and closed front machines. Some fingers may have to be removed when using closed-front machines. Faba and broad bean thresh easily but are prone to cracking, particularly kabuli types, so adjust thresher speed (400–600 rpm) and concave (10–30 mm) to suit. Removing alternate wires and blank-off plates from the concave will help reduce cracking. If possible cover the rasp bars with plate.

Harvesting grain at high moisture levels up to 14% should minimise cracking.

Harvest early before summer weeds become a problem to reduce clogging, staining and sample contamination. Desiccating the crop will kill summer weeds and ensure even crop ripening.

As faba and broad bean are destined for human consumption, a good sample off the header is usually required.

If the crop has lodged it is usually best to harvest into the opposite direction, or at right angles, to the direction the crop has fallen. Crop lifters may help. If sown on wide rows, use crop lifters and harvest up and back in the rows. The crop usually feeds in better over the knife section, and also provides the header operator with a better view of any rocks or sticks in the paddock.

Handling

Faba and especially broad beans are a very large, plump grain and are very prone to mechanical damage during handling. This especially applies to:

- Overly dry grain (below 10% Moisture Content).

- Crops that have been exposed to weather damage prior to harvest.

The use of tubulators or belt conveyors can reduce damage compared to conventional spiral augers.

Grain can be handled up to six times before delivery to receival points, so it is important that growers:

- Minimise the number of handling stages wherever possible.

- Use efficient handling techniques that minimise damage.

If using augers:

- Operate slow and full.

- Use large diameter augers.

- The flight pitch should be greater than the auger diameter.

- Length of the auger should be no longer than is necessary. The shorter the better.

- Keep auger incline as low as practical.

- Check flight casing clearance. Optimal clearance is typically 50% of grain size to minimise grain becoming wedged between the auger spiral and the casing ,and cracking.

- Auger drives should be at the discharge end, and not on the intake.

Re-cleaning of samples after harvest is sometimes necessary. Cereals can be cleaned from most pulses (not lentil) with a 3–4 mm rotary screen. The 3.75 mm slotted screen is popular and will help screen out split grain. The paddles or agitators in rotary screens should be either new or sufficiently worn so that the grain being harvested cannot jam between the outside of the paddle and the rotary screen. Screens or paddles can be damaged beyond repair if the grain jams. Fitting the screens with a spacer will provide additional clearance and so avoid the problem.

Milk thistle buds can be difficult to separate if they contaminate the sample because they are similar in size and weight to peas. However, if desiccated or given time to dry, the buds disintegrate when put through an auger and can be easily separated.

Dirt and most small weed seeds can be separated in rotary screens, however the dirt will increase component wear.

Storage

Grain quality is at its highest when first loaded into storage but can steadily deteriorate if the storage environment is not well-managed. A combination of good farm hygiene, storage choice and aeration cooling are important keys for maintaining grain quality and overcoming many problems with pests associated with storage.

Critical/key points to remember with regard to storing pulses are:

- Pulses stored above 12% moisture content require aeration cooling to maintain quality.

- Meticulous hygiene and aeration cooling are the first lines of defence against pest incursions.

- Fumigation is the only option available to control pests in stored pulses, which requires gas-tight, sealable storage.

- Avoiding mechanical damage to pulse seeds will maintain market quality, seed viability and be less attractive to insect pests.

Growers contemplating medium-long term storage (6–12 months) need to be aware that faba and broad bean continue to age, and quality will deteriorate in sunlight and over time.

All faba and broad beans will darken considerably in storage, and the rate of seed coat darkening (deterioration in grain colour) will be accelerated by:

- high seed moisture content

- high temperatures

- high relative humidity

- condition of the seed at harvest

- sunlight.

To maintain lighter seed coat colour and minimise darkening of seed, any pulses stored above 12% moisture content will require aeration cooling to maintain quality.

Mature seed subject to field weathering prior to harvest will deteriorate a lot quicker in storage, even if stored under ‘acceptable’ conditions of temperature and relative humidity.

Growers should avoid even short-medium storage of weather damaged grain.

Pulse grain placed in storage with high germination and vigour can remain viable for at least 3 years providing the moisture content of the grain does not exceed 11%.

Storage life of pulses is determined by temperature, moisture content, insects and diseases. Careful management of these factors is critical to avoid deterioration during storage.

When grain enters storage, it needs regular monitoring which allows early action and intervention to be taken if insects or grain quality issues arise. Monitoring grain at least monthly for insects, moulds, grain temperature and moisture should be standard practice.

For more detailed information: Storing Pulses (Stored Grain Hub)

Marketing, enduses and standards

It is expected that international demand for faba beans will continue to grow, but attention to quality is important to ensure market access.

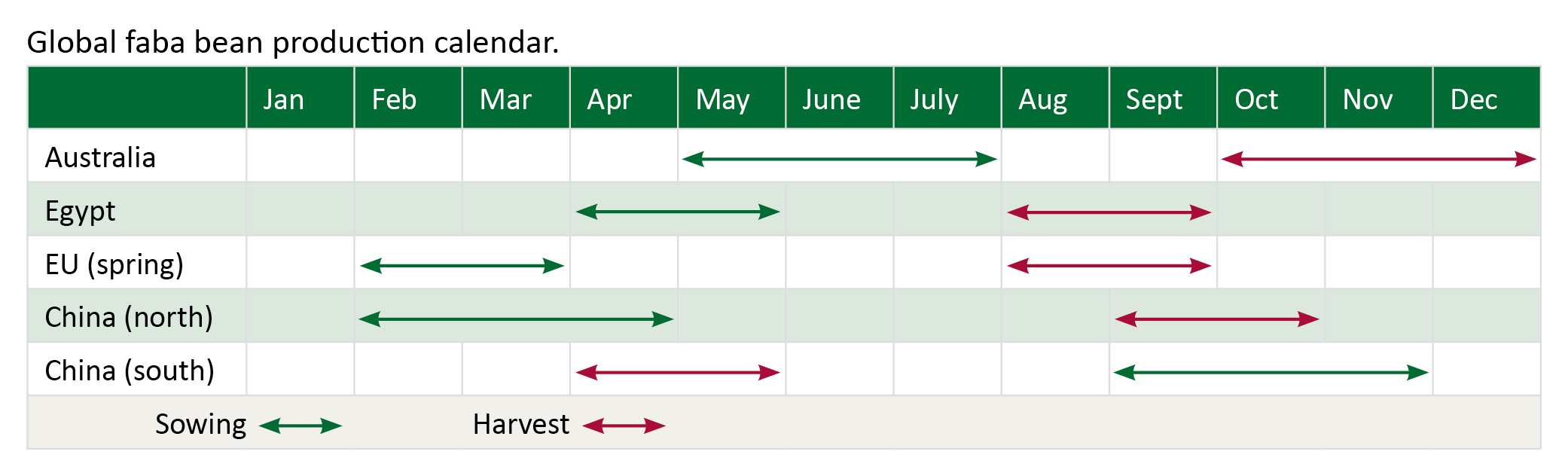

The major food markets for faba and broad beans are in the Middle East, with Egypt being the largest importer. There are several other medium sized importers and many small importers. Quality requirements, in terms of size and colour, differ between end-uses, e.g. splitting, canning or whole consumption, and also between markets. Australia is one of the major exporters of faba beans, along with France and the United Kingdom, and the actual amount exported by each of these countries varies from year to year. This depends on production, quality of product and demand, which to a large part is determined by production in Egypt.

To understand faba and broad bean markets, it helps to better understand what influences the situation with the major producers and users of beans.

- Cooked or baked – whole beans are used in soups, purees, baked goods, snack foods and in breakfast foods, or can be cooked into a thick gruel (‘foul mudammes').

- Ground – uncooked beans ground with other ingredients make falafel or tameya.

- Sprouts – sprouted for use in salads and stir-fries.

- Fresh – sold fresh in the pod or frozen.

Whilst the world production of faba and broad bean now exceeds 4.0 million tonnes annually, only about 2% of this production is traded internationally. The major exporting countries are Australia, France, and the United Kingdom. China was a major exporter of beans but has recently become an importer.

The relatively small volume is of faba beans traded insufficient to interest a transparent marketing system such as futures, which is available with other major grain commodities such as corn, wheat and canola.

The price of faba and broad bean as a commodity is relatively stable, rising and falling in line with supply and demand. Traditionally, there were stronger markets prior to the Ramadan festive season but this does not affect the market as strongly as it once did.

The relatively small tonnage traded also means that any delay in harvest or shipping in an exporting country can threaten a contract being met, resulting in a ‘short’ or ‘spike’ in the market. These are normally short term and reflect a contractual supply problem rather than a fluctuation in the bean market.

In recent years, the price of faba beans has generally shown a rising trend as production in the traditional countries has fluctuated often resulting in reduced production for a number of reasons. This situation is connected with insufficient expansion in the exporting countries to fill the demand.

Whilst ‘spikes’ and ‘shorts’ are hard to predict, the understanding of faba bean and broad bean marketing is improving throughout bean growing areas:

- With competition between local buyers.

- Improved communication between growers and marketers.

- Better access to information through a range of sources including Pulse Australia.

For more detailed information:

Receival standards

It is extremely important to monitor the quality of grain before and during harvest. Seed coat and kernel (cotyledon) can be discoloured by croptopping or premature desiccation in parts of the paddock if ripening is uneven. Staining of seed caused by green plants in the crop or admixture of splits, weeds, stones, etc., will only reduce the value of your grain and can lead to rejection or dockages. See Module 9, Marketing, Section 9.17 “Receival standards and visual quality charts for faba and broad bean (Section 9.18) that are part of those standards.

Visual appearance is everything. Human food markets demand a quality sample without cracking, staining, de-hulled seeds or insect damage. Pulse samples showing no header damage will always be more acceptable to a buyer. The large seed of faba bean makes it prone to mechanical damage. Minimising the number of times augers shift grain around helps reduce mechanical seed damage.

For more detailed information: Pulse receival and trading standards and Faba and broad bean quality defects

-

Faba bean: Bin burnt and heat damaged, mould and caked

-

Faba bean: poor colour

-

Faba bean: Insect damaged and sprouted

Key contacts

Pulse Australia Industry Development Managers

- Paul McIntosh

Phone: 0429 566 198 - Phil Bowden

Phone: 0427 201 946

Support and funding acknowledgement

Disclaimer

Information provided in this guide was correct at the time of the date shown below. No responsibility is accepted by Pulse Australia for any commercial outcomes from the use of information contained in this guide.

The information herein has been obtained from sources considered reliable but its accuracy and completeness cannot be guaranteed. No liability or responsibility is accepted for any errors or for any negligence, omissions in the contents, default or lack of care for any loss or damage whatsoever that may arise from actions based on any material contained in this publication.

Readers who act on this information do so at their own risk.

Copyright © 2015 Pulse Australia

All rights reserved. The information provided in the publication may not be reproduced in part or in full, in any form whatsoever, without the prior written consent of Pulse Australia. www.pulseaus.com.au

Last updated: 21 June 2016