Australian Pulse Bulletin

Pulse inoculation techniques

Profitable production of pulses is dependent on successful nodulation of the crop. Rhizobium bacteria that have a symbiotic relationship with pulse crops 'infect' the plant roots, forming nodules that fix atmospheric nitrogen for the pulse crop to use while it is growing. This free source of nitrogen ensures a healthy plant and delivers excess nitrogen that reduces the risks of cereal production in subsequent years.

All pulses have the same relative ability to fix nitrogen when inoculation of the plant has been successful. The residual nitrogen supply is determined by several factors, most notably the growth of the plant–more biomass production usually means more nitrogen fixation.

How much grain is harvested determines how much nitrogen is exported from the paddock, so higher yielding crops leave less residual nitrogen. Crops that grow well but produce low yields will leave more nitrogen behind. It’s difficult to provide an estimate for residual nitrogen values for each pulse in the varying environments of Australia.

New technology has provided growers with several methods of applying the Rhizobium bacteria to the soil. Application of essential fungicides at planting is also possible using these new delivery methods without compromising the health of the rhizobium.

-

Heavily nodulated lupin roots.

-

Peat inoculum can be applied with a low pressure applicator. The auger mixes the inoculant with the seed. Photo: P Munns

-

BASF 'Nodulator' granules.

-

ALOSCA clay granules.

-

A strong pink colour inside the nodules indicates that the rhizobia are actively fixing nitrogen. Photo: J Howieson

When to inoculate

Pulses require the application of a rhizobia species that is specific to that pulse. If a pulse has not previously been grown in the paddock then the crop must be inoculated at sowing.

Rhizobia will persist in the soil and, depending on a range of conditions, can inoculate a subsequent pulse. If the paddock has previously grown the same pulse, the number of rhizobia remaining in the soil will be affected by the:

- time since the pulse was last grown

- health of the crop

- type of rhizobia

- soil pH and texture.

Rhizobia types vary in their ability to persist in the soil until the host pulse crop is regrown. Lupin rhizobia (Group G) are most resilient and survive very well in low pH (down to pH 5) sandy soils. Pea and bean rhizobia (Groups E & F) survive well in neutral to alkaline soils with good texture (loams or clays).

If a well nodulated lupin or pea crop has been grown in the previous four years, a response to inoculation is less likely. However, pea and bean rhizobia survive poorly in low pH or sandy soils. The safest and least risk option is to inoculate the crop, especially on light textured soils.

Less is known of the survivability of chickpea rhizobia (Group N). Inoculating at sowing is recommended regardless of other considerations.

The cost of inoculation is low and worth the effort if there is any doubt about the viability of residual soil rhizobia.

A benefit of inoculating a crop where rhizobia already exist is that an improved strain will be introduced which could result in better persistence for future pulse crops. Research continues to find more robust and efficient rhizobia strains for all pulse species. The strain used today in any group will be more advanced than those introduced to a paddock in the past.

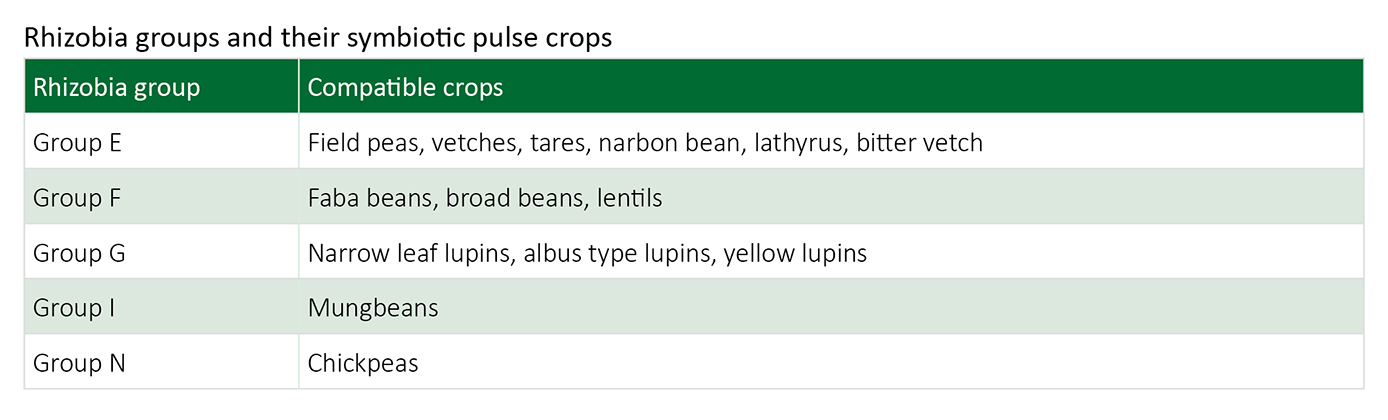

Inoculant groups

Inoculant packets or bags are clearly labelled with the pulse type they should be used on. The strains of rhizobia are specific to each pulse group and have been carefully selected to optimise nitrogen fixation. Care should be taken to ensure the correct type is applied.

Inoculant packaging includes instructions on methods for storing and inoculating seed . . . read them. Cool, dark storage is recommended. Never allow sun and heat to affect the inoculum packages.

While the strains are crop specific, Group E and F are somewhat interchangeable. For example, using group E on the Group F crops will ensure some nodulation. This is not so with Group N and G and the correct strain for the crop type is essential.

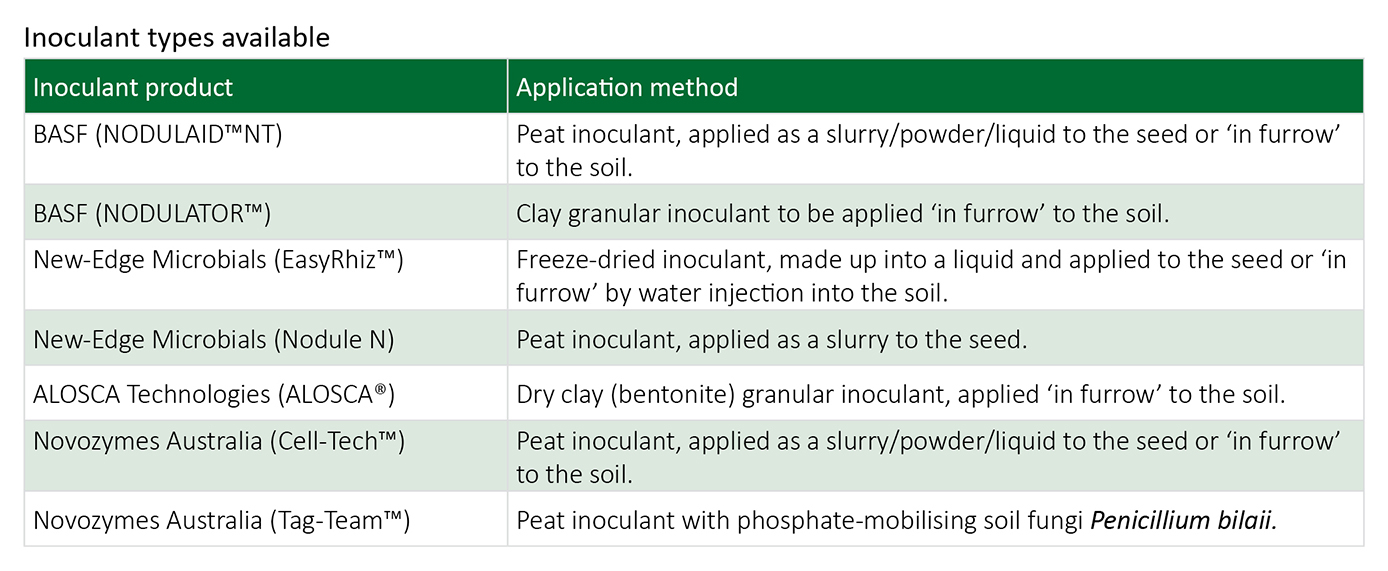

Inoculant types

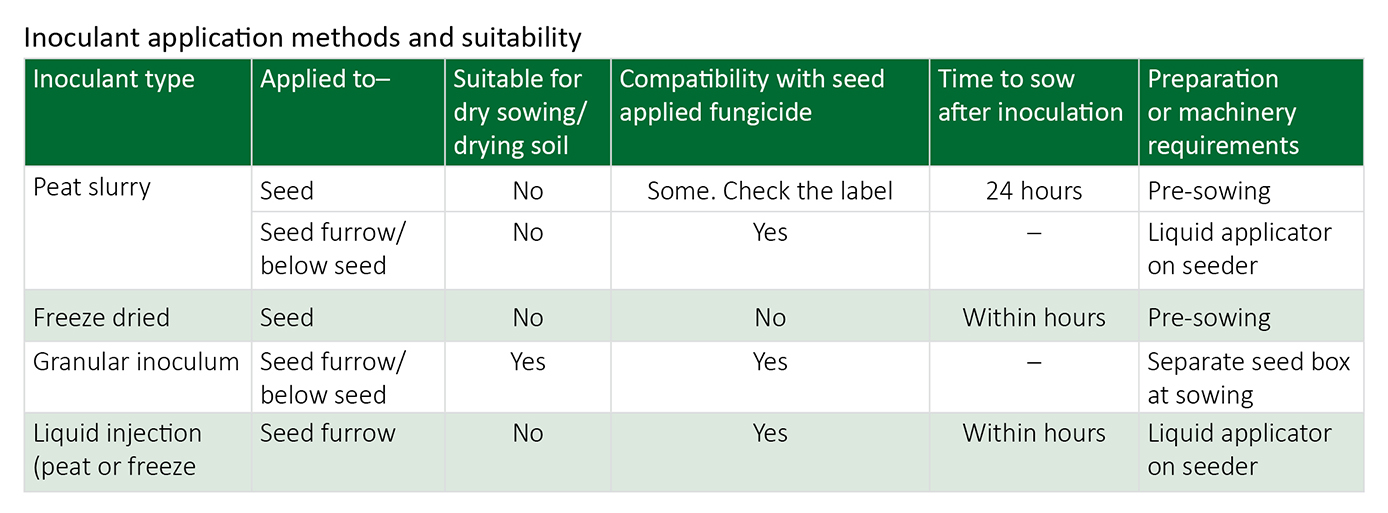

Peat inoculum

The traditional method of supplying rhizobia to seed is with peat inoculum. Read the label and apply the inoculant according to the directions. Most pulse crop inoculums for application to seed contain a pre-mixed sticker which helps adhesion to the seed. Be cautious and read the inoculant label regarding adding any approved insecticides, fungicides, herbicides, detergents or fertilisers into the slurry as these may be toxic to the rhizobia. Inoculated seed should be used within 24 hours when applied alone, and within 4 hours is applied in conjunction with a fungicide.

In-furrow water injection

Water or fluid injection of inoculants into the seed row is becoming more common as it has been adapted to pulse growing and modern machinery. It can be used where machines are set up for liquid N on cereals, and where fungicides are used to treat seeds before sowing. Water injection of inoculant requires at least 80 litres of water per hectare and is better with more.

The slurry-water solution is sprayed under low pressure into the soil in the seed row during seeding. Benefits of the new inoculant carrier types over peat are that they are convenient, ‘dissolve’ more readily, and do not have the requirement for filtering out peat hairs etc. Read the label before mixing any fungicides.

Granular forms

Granular inoculants are applied like fertiliser as a solid in the seed furrow or near to the seed and avoid many of the compatibility problems that rhizobia have with fertilisers and fungicides. They also eliminate the application procedures needed with peat inoculum. Granular inoculants also offer some advantages when dry sowing.

Granules contain fewer rhizobia per gram than peat based inoculants, so they must be applied at higher application rates. The size, form, uniformity, moisture content and rate of application of granules differ between products. Depending on the product or row spacing sown, application rates can vary from 4 kg/ha to 10 kg/ha to deliver adequate levels of nodulation.

Several granular inoculant formulations are now available, and they are not all the same in composition, practicalities of use and performance. Seek independent trial information for your area when making comparisons between products.

ALOSCA is a dry clay (Bentonite) granule now used in significant areas of Western Australia. BASF produces moist clay granules (Nodulator), while Novozymes Australia also produces a moist granular product.

Even application is best achieved through a dedicated third box on the seeder. Maintaining an even application rate when mixed with the seed is difficult as the granules shake down in the seed lot. Achieving an even distribution rate in the fertiliser box is also difficult, and rhizobia survival becomes an important consideration. Only ALOSCA claim compatibility when mixed with fertiliser.

Choosing an inoculant type

All types of inoculants will result in a well nodulated crop in good conditions. The choice of inoculant type by growers will depend on

- experience

- paddock history, i.e. the need for added rhizobium

- product availability

- relative cost

- perceived efficacy

- ease of use

- the suitability of machinery to deliver the inoculum.

Granules can vary and, depending on the product, may be dry or moist, uniform, variable, powdery, coarse or fine.

When conditions are less than ideal, making the right choice becomes more critical.

The rhizobia bacteria need moisture to survive. When contained in the carrier, ie the peat material or the granule form, they will survive for up to 12 months when stored well. Read the expiry date before use.

However, once applied the survival rate is highly dependent on available soil moisture. This particularly applies to inoculum applied to the seed or to the soil as slurry. Dry soil conditions after sowing will kill off the rhizobia. Moisture will be needed within 2-3 days after sowing to maintain adequate numbers. If introduced rhizobia are essential for crop health, dry sowing should be avoided and caution should be used if sowing into a drying seed bed with a poor forecast for follow-up rain.

Granules by comparison are ideally suited to maintaining rhizobia numbers in dry soil for extended periods before rain arrives. The rhizobium is maintained within the granule which continues to protect it until the soil wets and the rhizobia can start multiplying. They are ideal to use if dry sowing is being considered. Additionally they enable fungicides, which may be toxic to the rhizobia, to be applied the seed without causing a reduction in rhizobia numbers.

Application methods

Pesticide compatibility

Rhizobia are living organisms. As a general rule, pesticides are toxic to rhizobia.

Almost all pulses require a fungicide applied to the seed to provide protection during early growth against foliar diseases. Occasionally an insecticide may also be needed.

Peat inoculants are also applied to the seed, bringing together two largely incompatible products. Mixing inoculum with a pesticide for seed treatment is possible with some products. Read the inoculum label to check for compatibility. BASF claims compatibility between its peat inoculum and Rovral®. However, the seed must be sown within several hours into moist soil to avoid reducing rhizobia viability.

Applying the fungicide to the seed prior to the inoculum is a safer method to reduce the risk of rhizobia death. The fungicide can be applied at any time leading up to sowing. The inoculum is then applied immediately before sowing into moist soil. If in doubt, do not mix the inoculant and any pesticide.

Granular inoculants remove this risk because the rhizobia and the pesticide are not in contact. If you need to use a potentially toxic seed pesticide treatment, granular inoculant may be worth considering.

Always read the inoculant label or contact the manufacturer for up to date information on compatibility.

Check for nodulation

Don’t assume that by applying rhizobia to the crop that the job is over. It’s important to see how effective the inoculum has been and what state of health the nodules are in. By checking the degree of nodulation you can assess the type of inoculum product you have used and the application technique employed to get the rhizobia where it needs to be-in the roots of the growing pulse.

In good growing conditions, the roots will be heavily nodulated and have a healthy blood red colour. Provided that you have used the appropriate product in your operations, and the season is favourable for strong early growth, you will have set up your pulse crop for a strong yield. The bonus will be seen next year in a healthy cereal crop, growing on the residual nitrogen from the pulse plant.

Break open the root nodules to check the colour. A strong pink colour indicates the rhizobia are actively converting nitrogen for use by the plant-and next years cereal.

See also

- Inoculating legumes: a practical guide (GRDC)

- Inoculating legumes: the back pocket guide (GRDC)

- Rhizobia inoculants fact sheet (GRDC)

Talk with a local advisor to assess how much nitrogen you can expect from your pulse crop.

Key contacts

Disclaimer

Information provided in this guide was correct at the time of the date shown below. No responsibility is accepted by Pulse Australia for any commercial outcomes from the use of information contained in this guide.

The information herein has been obtained from sources considered reliable but its accuracy and completeness cannot be guaranteed. No liability or responsibility is accepted for any errors or for any negligence, omissions in the contents, default or lack of care for any loss or damage whatsoever that may arise from actions based on any material contained in this publication.

Readers who act on this information do so at their own risk.

Copyright © 2015 Pulse Australia

All rights reserved. The information provided in the publication may not be reproduced in part or in full, in any form whatsoever, without the prior written consent of Pulse Australia.

Last updated: 20 November 2015